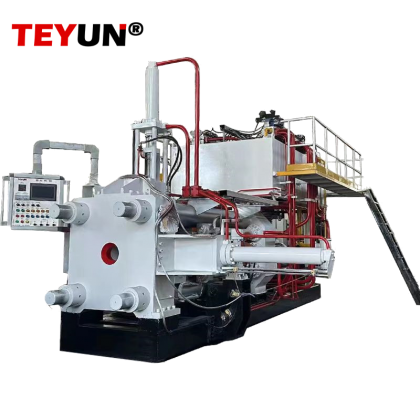

В ходе впечатляющего примера инженерной логистики, колоссальные 630-тонные портальные ножницы успешно начали свой путь с нашего производственного предприятия к ключевому клиенту в Мексике. Эта монументальная перевозка, потребовавшая инновационного и надежного транспортного решения, осуществлялась с использованием двух 40-футовых контейнеров Flat Rack (40FR) и одного 40-футового контейнера High Cube (40HQ).

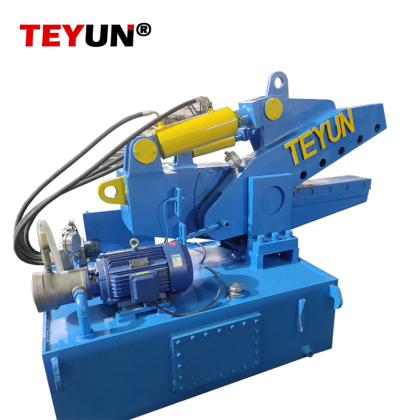

This specific gantry shear, a flagship model of our heavy-duty recycling equipment line, represents a significant investment in advanced metal processing capabilities for our Mexican partner. Designed for extreme durability and high-volume throughput, it is set to become a centerpiece in their scrap yard operations, dramatically enhancing their efficiency in processing ferrous materials.

The dispatch of such a massive, non-containerizable item presented a unique logistical challenge. Our engineering and shipping teams meticulously planned the loading and securing process. The main structure of the shear was expertly mounted and fastened onto the two 40FR containers, which provide an open-side, platform-style transport ideal for oversized cargo. Critical auxiliary components, electrical systems, and tools were securely packed within the accompanying 40HQ container, ensuring everything arrives simultaneously and ready for assembly.

"This shipment is a testament to our capability to deliver turnkey heavy industrial solutions anywhere in the world," said the project manager. "Moving 630 tons of precision machinery across continents requires flawless coordination between manufacturing, engineering, and logistics partners. We are thrilled to see this powerhouse unit on its way to empower our client's operations in Mexico."

The client, a leading player in Mexico's recycling and steel industry, selected this gantry shear for its unparalleled cutting force, reliability, and advanced control systems. Upon installation, it will enable efficient processing of large-scale scrap, including entire automobiles, industrial fabrications, and demolition steel, contributing to a more sustainable and productive metal recycling ecosystem.

The successful loading and departure mark a critical milestone in this international project. Our technical supervision team will now prepare to provide on-site assistance for the unloading, installation, and commissioning phases, ensuring a smooth transition to full operational status.

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

Поддерживается сеть IPv6

Поддерживается сеть IPv6