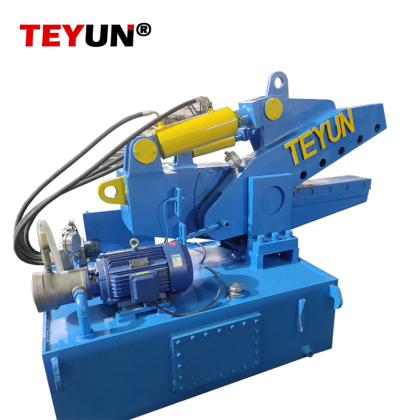

Тигровый ножницы

Имеет решающее значение в сфере переработки лома. Работает на мощной гидравлической системе. Гидравлическое масло высокого давления приводит в движение поршень, заставляя подвижное лезвие резать неподвижное. Этот механизм позволяет ему создавать большое усилие сдвига и резать различные материалы.

В переработке лома,

тигровый ножницы

Имеет множество применений. Он измельчает крупногабаритный лом, упрощая его обработку, транспортировку и обработку. Например, он может резать толстые металлические листы, кузова автомобилей и крупные куски пластика. Резка лома на более мелкие части увеличивает площадь поверхности, что благоприятно сказывается на последующих процессах переработки, таких как плавка или измельчение, и повышает эффективность переработки. Кроме того, точная резка обеспечивает высокое качество конечного продукта и более эффективное разделение материалов.

На заводе по переработке металла,

тигровый ножницы

Использовался для обработки старых стальных балок. Он позволяет быстро разрезать их на отрезки нужной длины, значительно сокращая время обработки по сравнению с ручной резкой. На заводе по переработке пластика он эффективно резал большие пластиковые трубы, обеспечивая более эффективную грануляцию.

Понимание технического паспорта производителя имеет важное значение для принятия правильных решений.

1.Сила сдвига:

Это самый важный параметр, напрямую определяющий толщину и твердость материалов, которые может резать станок.

2. Длина лезвия:

Определяет ширину материала, который можно разрезать за один раз. Стандартная длина варьируется от 600 до 1000 мм и более.

3.Мощность основного блока (кВт):

Мощность двигателя, приводящего в действие гидравлическую станцию, влияет на энергопотребление и бесперебойность работы.

4. Ширина раскрытия/Ход цилиндра (мм):

Определяет максимальную высоту (или толщину) материала, который может быть загружен.

5.Частота сдвига (мин):

Теоретически, это количество циклов, которые лезвие может совершить в минуту. Фактическая рабочая частота зависит от скорости вращения.

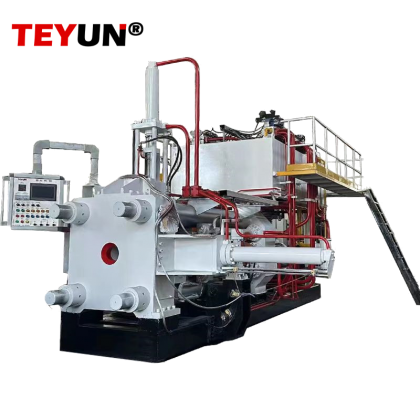

6.Система управления:

Стандартное релейное управление: экономично и просто в обслуживании.

Управление с помощью ПЛК (программируемого логического контроллера): высокая стабильность, мощная функциональность, простота интеграции с системами автоматизации (например, с конвейерами) и удобная диагностика неисправностей. Рекомендуемый выбор.

Компания Tiger Shear вносит значительный вклад в защиту окружающей среды и циклическое использование ресурсов. Эффективная переработка лома сокращает потребность в добыче первичного сырья, сохраняя природные ресурсы. Кроме того, правильная переработка лома минимизирует количество отходов, отправляемых на свалки, тем самым снижая загрязнение окружающей среды. Если вам нужна помощь, свяжитесь с нами.

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

Поддерживается сеть IPv6

Поддерживается сеть IPv6