Ключевые моменты (анализ спроса)

1. Характеристики сырья

Тип металла: это тонкий, легкий стальной лом, листовой металл, корпуса банок (например, кузова автомобилей, гофрированные стальные листы) или тяжелый, тяжелый стальной лом, конструкционная сталь, арматура или детали отработанных автомобилей? Различные материалы имеют совершенно разную плотность и прочность.

Форма и размеры: максимальные исходные размеры (длина, ширина, высота) и толщина сырья; наличие запутывания.

Предварительная обработка: Измельчалась ли или разрезалась ли древесина? Это напрямую влияет на плотность и эффективность прессования.

2. Требования к производительности и эффективности

Суточная/почасовая производительность (тонны): это ключевой показатель, определяющий масштаб оборудования (давление в главном цилиндре, размер тюка).

График работы: односменный, двухсменный или непрерывный? Это влияет на прочность конструкции оборудования и мощность системы охлаждения гидравлической системы.

3. Требования к готовым тюкам

Размеры тюка (длина x ширина x высота): должны соответствовать стандартам последующих металлургических заводов или транспортных компаний.

Плотность связки (тонн/куб. метр): Тюки высокой плотности (обычно более 2,2 тонн/куб. метр для тяжелой техники) легче транспортировать и плавить, но и стоят дороже.

Вес связки: Идеальный диапазон веса для каждого тюка.

4. Энергетические и вспомогательные сооружения

Доступные источники питания: стандартное трехфазное напряжение 380 В, но для моделей большей мощности может потребоваться более высокое напряжение или трансформатор.

Условия эксплуатации объекта: монтажное пространство (длина, ширина, высота, особенно глубина котлована), несущая способность фундамента, грузоподъемность мостового крана.

Охлаждение гидравлического масла: водяное или воздушное? Зависит от местного климата и рабочей нагрузки.

Основные параметры компонентов

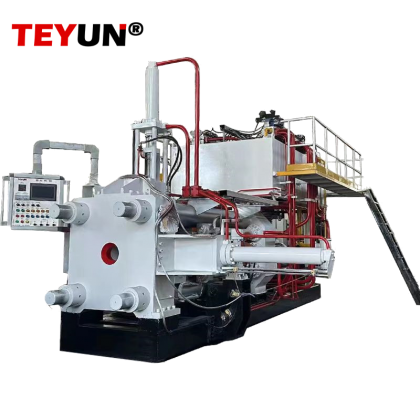

Давление в основной системе (тонны): наиболее важный параметр, определяющий конечную силу сжатия. Более высокое давление приводит к большей плотности упаковки.

Размеры затвора (внутренние габариты полости): Определяет максимальный размер сырья, которое можно поместить внутрь, и размер готового тюка.

Размеры камеры сжатия: фактический размер спрессованного тюка; его необходимо учитывать в сочетании с размером бокала.

Диаметр и ход поршня главного цилиндра: влияют на усилие сжатия и скорость сжатия.

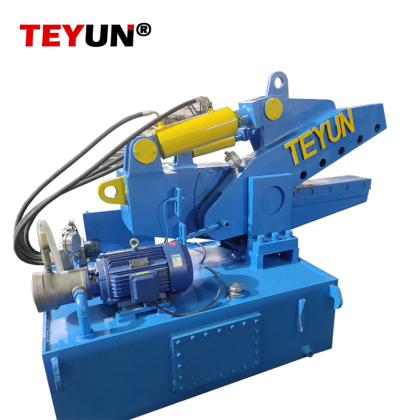

Механизм запирания двери: должен быть прочным и надежным, чтобы обеспечить безопасность в условиях высокого давления. Гидравлические замки более совершенны и надежны, чем механические.

Конструкция головки пресса: Раздельная конструкция для «предварительного сжатия» и «основного сжатия» повышает эффективность; сначала сжимается объем, затем происходит формование под высоким давлением.

Метод управления: Автоматическое управление с помощью ПЛК (программируемого логического контроллера) является современным стандартом, более стабильным, интеллектуальным и простым в обслуживании, чем релейное управление.

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

Поддерживается сеть IPv6

Поддерживается сеть IPv6