В бурлящем центре современной промышленности, где эффективность и устойчивое развитие уже не идеалы, а необходимость, мощная, но часто упускаемая из виду машина оказывает огромное влияние:

машина для брикетирования металла

. Эти надёжные устройства являются краеугольным камнем циклической экономики в металлургии, превращая то, что когда-то считалось грязными, опасными и малоценными отходами, в чистый, прибыльный и пригодный для повторного использования ресурс.

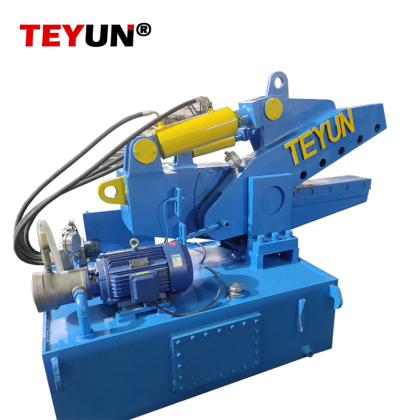

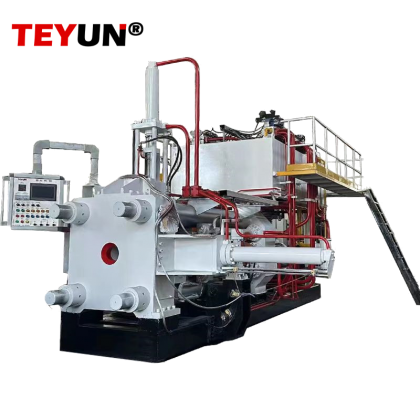

По сути, брикетировочный пресс для металла представляет собой гидравлический пресс, который оказывает огромное давление на рыхлые металлические отходы, часто называемые «стружкой» или «стружкой», и прессует их в плотные, однородные блоки, известные как брикеты. Этот простой процесс прессования меняет правила игры. Сырьё, которое может варьироваться от алюминия и меди до стали, чугуна и даже титана, обычно производится в огромных количествах в процессе механической обработки, такой как фрезерование, точение и сверление. В рыхлом виде эти отходы представляют собой проблему. Они занимают ценное пространство на полу, представляют опасность из-за острых кромок, могут быть пожароопасны при пропитывании легковоспламеняющимися смазочно-охлаждающими жидкостями, а также неэффективны и дороги в транспортировке.

Процесс брикетирования элегантно решает эти проблемы. Сжимая материал, эти машины достигают значительного уменьшения объёма, часто в 10 раз и более. Это мгновенно освобождает производственное пространство, упрощает поддержание чистоты и улучшает общую рабочую среду. Получаемые брикеты сухие, прочные и удобные в обращении. Их можно аккуратно складывать на поддоны, безопасно хранить на открытом воздухе и перевозить стандартными логистическими системами, что значительно снижает транспортные расходы.

Однако преимущества выходят далеко за рамки простого удобства. Экономические и экологические преимущества весьма существенны.

От центра затрат к источнику доходов

Для производственных предприятий металлолом традиционно считался расходным материалом: его сбор, обработка и утилизация были сопряжены с большими затратами. Брикетировочная машина меняет эту модель. Превращая лом в брикеты высокой плотности, этот материал становится востребованным товаром для переработчиков металла и литейных цехов. Брикеты эффективнее плавить в печах благодаря высокому соотношению массы к площади поверхности, что приводит к меньшему окислению и потерям металла (выходу годного). Следовательно, переработчики платят более высокую цену за брикетированный металл по сравнению с сыпучей, маслянистой стружкой. Это превращает поток отходов в значительный источник вторичного дохода, часто обеспечивая быструю окупаемость инвестиций в саму брикетировочную машину.

Основа зеленого производства

В эпоху повышенного внимания к вопросам экологии брикетирование – это очевидный выигрыш в плане устойчивого развития. Во-первых, оно способствует переработке ценного сырья, снижая потребность в энергоёмком производстве первичного металла. Например, переработка алюминия требует всего около 5% энергии, необходимой для его производства из руды. Во-вторых, многие современные системы брикетирования включают в себя интегрированный процесс экстракции, который позволяет отжимать смазочно-охлаждающие жидкости и масла, содержащиеся в стружке. Эту восстановленную жидкость часто можно отфильтровать и повторно использовать в процессе обработки, что дополнительно снижает потребление и затраты на утилизацию. Полученные брикеты также более экологичны, что приводит к снижению выбросов при переплавке.

Технология, лежащая в основе трансформации

Современные машины для брикетирования металла

Это чудо инженерной мысли, сочетающее в себе мощь и точность. Они обычно оснащены мощной гидравлической системой, способной создавать давление в сотни тонн, закаленной стальной формой, определяющей форму брикета (обычно цилиндра или прямоугольного параллелепипеда), и сложной системой управления, обеспечивающей стабильную работу. Безопасность имеет первостепенное значение: блокируемые ограждения обеспечивают защиту оператора.

От обширных автомобильных заводов до специализированных мастерских аэрокосмической отрасли – брикетировочные машины для металла стали незаменимыми. Это молчаливые гиганты, работающие в тени, превращающие хаотичные побочные продукты производства в упорядоченные и ценные активы. Они служат убедительным подтверждением идеи о том, что в современном мире истинная эффективность заключается не только в производстве вещей, но и в управлении всем жизненным циклом наших ресурсов с помощью интеллекта и предвидения.

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

Поддерживается сеть IPv6

Поддерживается сеть IPv6