В суровом и требовательном мире переработки металлолома и сноса зданий эффективность и необузданная мощность имеют первостепенное значение. Среди всего арсенала оборудования, используемого на этих складах, одна машина выделяется уникальным сочетанием простоты, долговечности и грубой силы:

машинка для стрижки аллигаторов по металлу

. Этот прочный инструмент, названный так из-за своего характерного режущего действия, напоминающего крокодила, является краеугольным камнем измельчения материалов, превращая громоздкий лом в удобные для переработки детали.

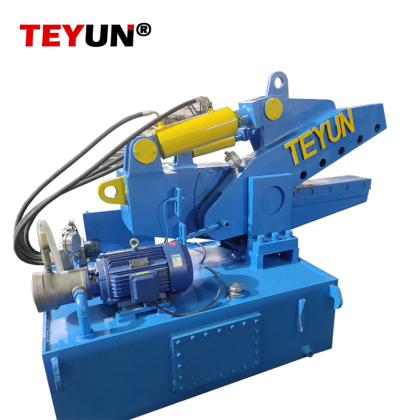

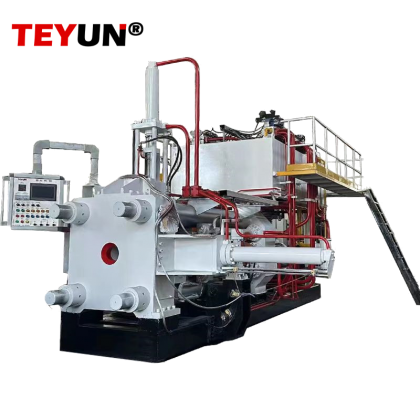

По своей сути, аллигаторные ножницы представляют собой механическое или

гильотинные ножницы с гидравлическим приводом

В отличие от более сложных пресс-подборщиков или грануляторов, его принцип работы прост и интуитивно понятен. Машина оснащена фиксированной нижней челюстью и мощной верхней, которая опускается с огромной силой, вгрызаясь в металл одним решительным движением. Это ножничное действие невероятно эффективно для широкого спектра материалов, включая стальную арматуру, трубы, тросы, строительные балки и даже смешанные металлы из снесенных транспортных средств и оборудования. Его основная задача — не создание единообразных форм, а эффективное уменьшение размеров крупных и неудобных предметов, которые иначе было бы невозможно обрабатывать или транспортировать.

Эффективность ножниц «Аллигатор» обусловлена их прочной конструкцией и источником питания. Современные модели преимущественно гидравлические, что обеспечивает значительные преимущества. Гидравлический блок питания приводит в движение режущую раму, создавая огромное усилие резки, измеряемое тоннами. Эта система обеспечивает контролируемые, мощные удары и часто оснащена предохранительными клапанами, предотвращающими перегрузку. Лезвия ножниц изготовлены из высококачественной термообработанной легированной стали и рассчитаны на высокие ударные нагрузки и истирание. Хотя со временем они затупляются, их конструкция обеспечивает простую замену или заточку, сводя к минимуму время простоя.

Использование аллигаторных ножниц имеет множество преимуществ. Их главное преимущество — высокая надёжность. Благодаря меньшему количеству сложных движущихся частей, чем у других обрабатывающих машин, они менее подвержены поломкам и проще в обслуживании, что крайне важно в суровых промышленных условиях. Эта простота также обеспечивает снижение первоначальных инвестиций и эксплуатационных расходов, делая их доступным решением для небольших и средних складов. Более того, их универсальность является важным преимуществом. Возможность обработки разнообразных материалов — от толстого медного кабеля до двутавровых балок из закалённой стали — делает их незаменимым первым этапом в цепочке переработки, подготавливая лом к дальнейшей сортировке и переплавке.

Операция и бдительность

Во время работы бдительность имеет решающее значение для безопасности и производительности. Операторы должны обращать внимание на следующее:

-

Аномальные шумы и вибрации:

Нормальный звук среза – глухой.

глухой стук

. Любой резкий скрежет, ударные звуки или нерегулярные вибрации требуют немедленного отключения для проверки.

-

Мониторинг температуры:

Необходимо проверить основные компоненты на перегрев. Температура гидравлической системы (корпуса насоса и двигателя) обычно не должна превышать 60–70 °C (неприятно тёплая на ощупь). Аномально высокая температура может указывать на закупорку масляного контура, ухудшение качества рабочей жидкости или внутренние утечки. Также необходимо контролировать состояние корпусов подшипников и главного двигателя.

-

Обнаружение утечек:

Необходимо постоянно осматривать гидравлические линии, соединения и цилиндры на предмет наличия признаков утечки жидкости.

-

Наблюдение за эффективностью:

Заметное уменьшение усилия сдвига или замедленное движение могут указывать на такие проблемы, как недостаточное давление в системе или внутренняя утечка в цилиндре.

В заключение, машинка для резки металла «Аллигатор» – это воплощение принципа, согласно которому функция диктует форму. Возможно, ей не хватает высокотехнологичной продвинутости роботизированного сортировочного манипулятора или огромного шредера, но её роль незаменима. Как безжалостные «челюсти» свалки металлолома, она воплощает собой серьёзный подход к сложной работе, обеспечивая грубую, бескомпромиссную мощь, необходимую для того, чтобы перегрызть кости нашей отработанной инфраструктуры и обеспечить бесконечный цикл переработки металла.

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Адрес : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

Поддерживается сеть IPv6

Поддерживается сеть IPv6